Windshield replacement is more complex than ever due to advancements in automotive technology, integrated safety systems, and changing glass manufacturing standards. Modern vehicles rely on the windshield as both a structural and technological component, meaning that replacement is no longer just about removing broken glass and installing a new one. Understanding what makes the process more demanding helps vehicle owners make informed decisions and avoid costly mistakes.

The Role of Advanced Driver Assistance Systems

Modern windshields often include built-in Advanced Driver Assistance Systems. These systems are linked to cameras, sensors, and radar units positioned behind or around the windshield, which support features such as:

- Lane departure alerts

- Forward collision warning

- Adaptive cruise control

- Automatic emergency braking

Even slight changes in positioning or alignment can throw off these features. After installation, recalibration is required to ensure accuracy and performance, and this adds time, cost, and specialized labor.

Static and Dynamic Recalibration Requirements

Technicians must choose between static recalibration, dynamic recalibration, or a combination based on manufacturer instructions.

- Static recalibration is performed in a controlled shop environment with laser-guided equipment

- Dynamic recalibration requires test-driving the vehicle following specific guidelines

If recalibration is skipped or done incorrectly, safety technology may malfunction without the driver realizing it.

Changes in Windshield Manufacturing and Materials

Windshields are no longer simple laminated glass panels. Manufacturing has become more advanced, stronger, and more customized for each vehicle model.

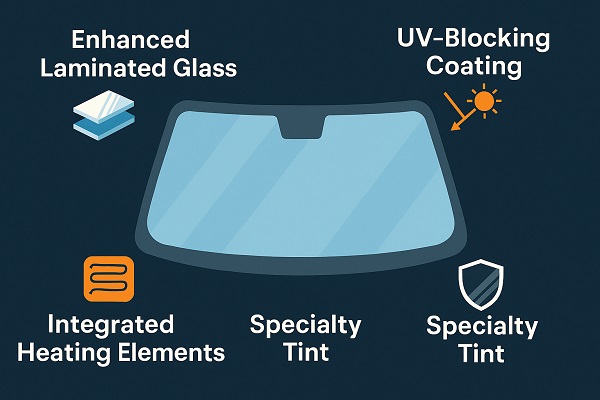

Key Material and Design Differences

- Enhanced laminated glass with built-in acoustic layers

- UV-blocking coatings

- Integrated heating elements or built-in defrost lines

- Specialty tinting that matches factory specifications

These upgrades improve comfort and safety but make windshield replacement more precise and method-specific.

Calibration and Precision Installation

Modern auto glass replacement requires exact installation measurements. Even a fraction of a millimeter off center can affect sensor alignment or air sealing. A windshield now contributes to:

- Correct deployment of passenger-side airbags

- Structural integrity during rollovers

- Soundproofing performance

- Resistance to wind and weather intrusion

Improper installation can weaken roof support and put passengers at risk, so professional service is more critical than ever.

Compatibility with Manufacturer Specifications

Vehicle manufacturers release model-specific guidelines that dictate which type of windshield and adhesive must be used. Using aftermarket glass that does not follow the original specifications may lead to:

- Poor ADAS functionality

- Visibility distortion

- Increased cabin noise

- Reduced resale value

Many vehicles now require OEM or certified replacement glass to maintain technology accuracy.

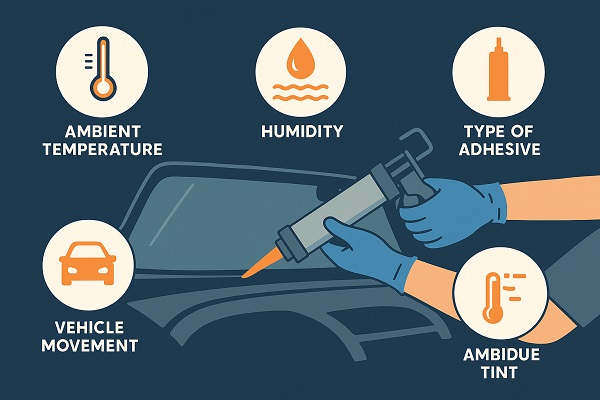

The Impact of Advanced Sealants and Adhesive Curing

Modern adhesives are engineered for high-strength bonding and crash resistance. Proper curing times and climate requirements must be followed to achieve safe drive-away time.

Factors That Affect Curing

- Ambient temperature

- Humidity levels

- Type of adhesive

- Vehicle movement or vibration

Skipping safety wait times may cause air leaks, compromised bonding, or weakened crash protection.

Why Professional Certification Matters

Windshield replacement requires technicians to understand electronic systems, vehicle diagnostics, and manufacturer procedures. Shops that invest in certified training, calibration technology, and OEM-approved tools are more equipped to perform high-quality work.

Benefits of Choosing Certified Technicians

- Accurate ADAS calibration

- Proper glass matching

- Correct adhesive application

- Reduced risk of costly rework

This ensures safety systems operate as intended after replacement.

Insurance and Warranty Considerations

Insurance companies are increasingly aware of the complexity of windshield replacement and often require calibration documentation or certified glass. Failing to meet standards may void warranties or delay insurance claims.

Key considerations include:

- Whether OEM parts are covered

- If recalibration is included in the claim

- Shop qualification or preferred provider status

Understanding these factors helps avoid unexpected expenses.

Cost Factors and Why Pricing Varies

Windshield replacement costs more today due to integrated technology, calibration equipment, and the labor skill needed. Costs may vary based on:

- Vehicle make and model

- Complexity of attached components

- Type of replacement glass

- Recalibration requirements

Although cheaper options may seem appealing, they can lead to long-term safety issues and additional expenses.

Signs Your Replacement Needs Professional Review

Even after installation, there are warning signs that something may be off:

- Wind noise at highway speed

- Fogging or moisture near edges

- ADAS warnings or dashboard alerts

- Visible distortion or improper alignment

Addressing issues early helps prevent further damage or safety hazards.

Why Quality Matters More Than Speed

With so many variables involved, rushing the job can lead to improper sealing, inaccurate calibration, or glass instability. Choosing a shop with proper tools and training provides long-term vehicle safety and performance, even if it takes more time than a basic installation.

Selecting qualified professionals and understanding what goes into the service ensures the windshield maintains its role as a safety feature, not just a visibility component. Reliable windshield replacement protects your driving experience, preserves the value of your vehicle, and ensures critical systems continue working the way they were designed.

Content reviewed and published by SLP AutoGlass Editorial Team.